Manufacturing

The most Swedish frame there is. We have gone to great lengths to ensure that as much as possible is done in Sweden. Every step of the way has been precisely tuned to ensure the highest quality possible. The fibers are manufactured in Japan, then sent to Sweden to be woven into TeXtreme. The fibers are then sent to England to be pre-impregnated. When they come back they are layered in the correct orientation and then pressed with heat to create the carbon fiber plates.

CNC Milling

After the plates are made, over 1200 holes are milled in each plate. To ensure a smooth transition to the next machine reference holes are made. This is to make sure both machines coordinate systems are aligned.

Micro Waterjet Cutter

After the plates have been cut into Swiss cheese they get to the final step. We use a micro waterjet cutter with a nozzle diameter of 0,3mm to cut the parts with speeds up to 2,5m/min. Due to its 0,3mm nozzle all inner corners only have a radius of 0,15mm. This is almost none-existant radiuses. Meaning a much bigger contact area between plates in slot and tab connections. This bigger contact area drastically increases durability.

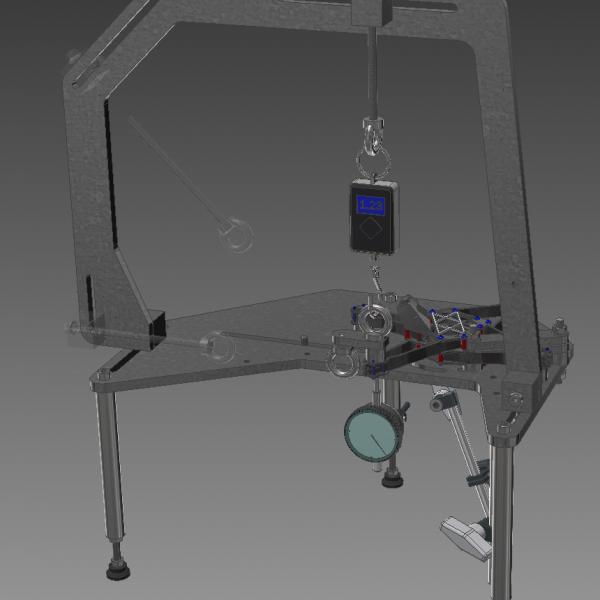

Testing

The final parts are inspected and tested to ensure quality. We also do non-destructive tests of diffrent frame designs. You can find out more about our testing on our testing page. Everything we make is tested. Screws and battery straps included.